Isaac’s Story From Broken Bus to Father & Son Road Trip

⏱ Time to Complete: Several months of preparation and build-out

🔧 Tools Used: Angle grinder, welder, paint sprayer, hand tools, impact driver

💡 Key Learning: Big projects need space to spread out and time to figure things out

🎯 Skill Level: Hands-on military experience, first bus conversion

📍 Location: Norfolk

The Problem

Isaac was transitioning out of the Navy and ready for his next adventure. He bought a school bus with plans to convert it into a home on wheels for long-distance travel.

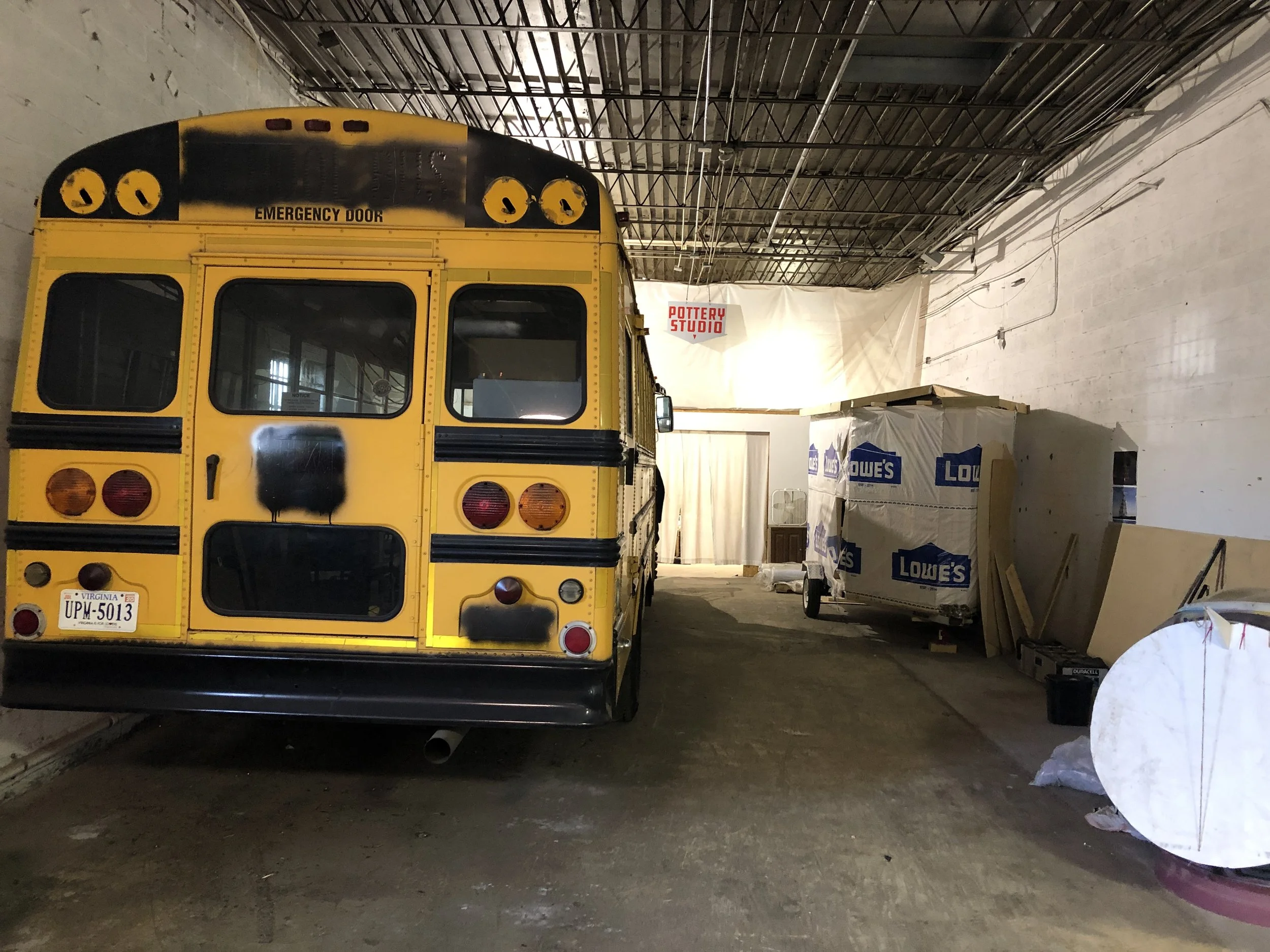

The problem was simple: you can't gut, rebuild, and paint a 35-foot school bus in an apartment parking lot. Or a storage unit. Or most driveways in Hampton Roads.

He needed space. Real space. And access to tools he didn't own and couldn't justify buying for a single project.

Isaac brought his bus to 757 Makerspace.

The Build

Isaac started by stripping the bus down. Seats came out. Old flooring was removed. The interior was gutted to bare metal.

Then came the real work. Insulating walls and ceiling. Running electrical. Prepping and painting the exterior. Installing new flooring. Building out the basics to make the bus livable for travel.

He worked with a deadline. His first long-distance trip with his father was scheduled, and the bus needed to be road-ready.

At 757 Makerspace, Isaac had what he needed: indoor space to work regardless of weather, tools for metalwork and fabrication, a paint booth for the exterior, and a community of people who'd done similar builds before.

The Outcome

Isaac finished the conversion in time. The bus was road-ready, and he hit the road with his father for their first adventure together.

Since Isaac's build, we've hosted 12 skoolie conversions, 8 van builds, 1 Winnebago conversion, 1 Airstream interior rebuild, 2 tiny house builds, and 1 teardrop trailer build. Every one of them faced the same problem: where do you work on a project this big?

Here's what made it possible:

Space big enough for the project. Isaac's bus was 35 feet long. It fit inside with room to work around it. You can't do that in a typical garage or driveway in Hampton Roads.

Tools you need but don't own. Angle grinders, welders, paint sprayers, impact drivers, and hand tools. Isaac used what was available.

Time and flexibility. Isaac worked nights and weekends over several months. He had 24/7 access and could come in whenever he had time to work.

People who'd done it before. Other members had built out vans, buses, and trailers. When Isaac hit a snag, someone was around to talk through it.

You don't need to own a bus to understand the appeal of this story. The principle is the same for anyone with a big project: if you don't have the space or tools to do it at home, you're stuck.

Ready to start your build?

If you have a project that's too big, too messy, or too complicated to do at home, let's talk.

👉 Schedule Your Free Tour we'll show you the space, walk through what tools are available, and have an honest conversation about whether we're the right fit for your project.